- How a scanning galvanometer works

- What is the classification of scanning galvanometer

- Laser, galvanometer and other core components of 3D printers are being replaced by domestic ones on the road

E-mail:support@hmmescan.com

TEL:0086-400-859-7098

Address:B705-2, Oil Pine Technology Building, No. 958 Honghua Road, Longhua District, Shenzhen

How a scanning galvanometer works

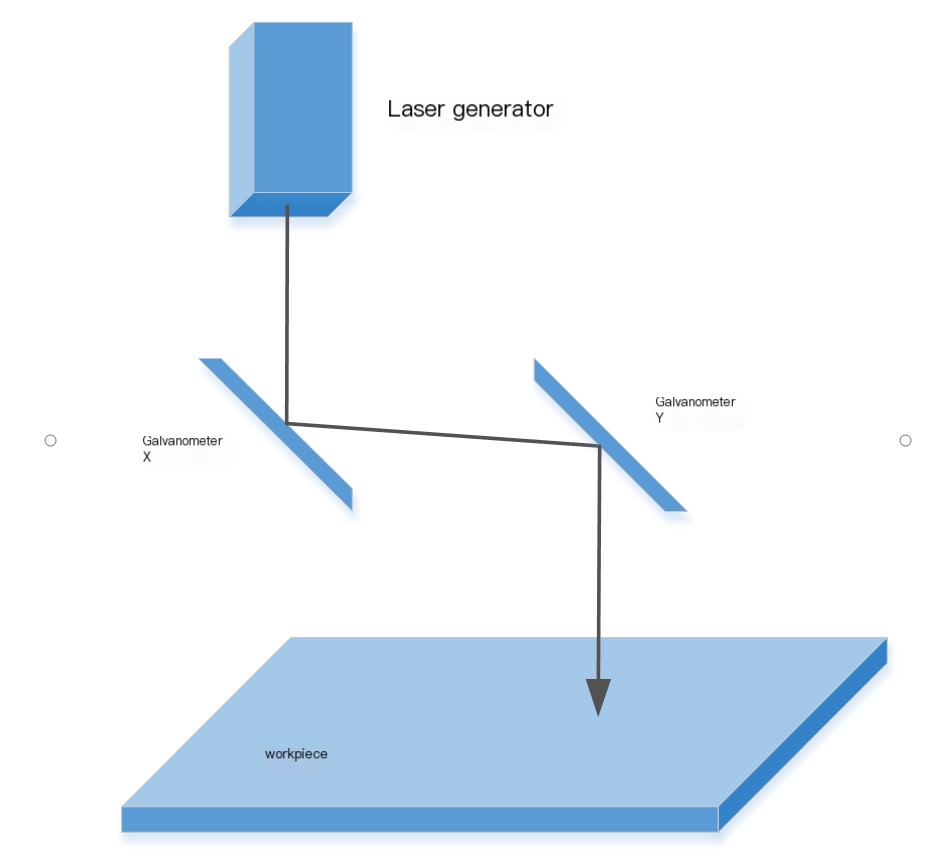

Laser galvanometer is a special motion device specially used in the field of laser processing, it relies on two galvanometers to reflect the laser to form the motion in XY plane. Laser galvanometer is different from general motor, laser galvanometer has very small inertia, and in the process of movement of the load is very small, there are only two small reflective lenses X and Y, respectively, with different motor control deflection, the system response is very fast.

In the process of jumping movement, the axis moves to the position to be processed, and the laser is off, which does not affect the processing of the trajectory, so it can move at a very high speed. During the marking movement, the laser is turned on to process the trajectory, so the user needs to set the appropriate speed of movement according to the actual processing requirements.

The galvanometer is an excellent vector scanning device. It is a special oscillating motor (laser vibrator), the basic principle is to energize the coil in the magnetic field to generate torque, but different from the rotating motor, its rotor through the mechanical new spring or electronic methods plus a reset torque, the size and the rotor deviation from the equilibrium position of the angle is proportional to the current and the rotor deflected to a certain angle, the electromagnetic torque and the size of the restoring torque is equal, so it can not be like a normal motor like rotation, can only be deflected, deflection angle is proportional to the current. Therefore, it can not rotate like an ordinary motor, but can only be deflected, and the deflection angle is proportional to the current.

The vibrating mirror system consists of the above parts to form a basic system, in which the main components of the vibrating lens for the X / Y two mirrors, respectively, to control the rotation of the X / Y lens of the two motors, according to the actual needs of the human-machine operating system can also be added, encoder and so on.

Because the laser marking machine relies on the X / Y oscillator deflection of the cooperation, the laser will be reflected to the table surface, for accurate engraving. The control of the oscillator is controlled by the controller open-loop control, so the requirements must be linear, that is, the input signal with the deflection angle is a linear relationship between. Because the vibration mirror is a fast precision machinery, so it is required from one working state to another working state requires the acceleration of the greater the better, so that the marking of empty time is infinitely small.

Scanner motion adopts buffer motion mode, that is, the user needs to transfer motion and process data to the axis motion buffer, and then start the buffer motion, the motion controller will sequentially and continuously execute the motion data transferred by the user until all the motion data are all motion completed. In the laser galvanometer motion control system there is not only motion control, but also laser control. How to effectively deal with the galvanometer motion and laser switch with is a very important issue, only effective coordination of the laser and the relationship between the motion, in order to move a precise trajectory.

It is mainly used for laser marking, including laser cutting, stage lighting control, laser perforation and so on. It is a non-contact, non-polluting, non-abrasive new marking process with automated control and greatly improved reliability. Laser marking is the use of high energy density laser beam, with the laser beam on the surface of the material regular movement, while controlling the laser beam on and off, so that the surface of the target material physical or chemical changes, the laser beam can be processed on the surface of the material to create a designated pattern.

Compared with the traditional marking process, laser marking has the following advantages: fast marking speed, clear handwriting. Non-contact processing, low pollution, no wear and tear. Easy to work, strong anti-counterfeiting ability. High-speed automatic operation, low production cost, reliable operation.